Application Fields

Technology R & D

|

| Inner wall decoration of yachts and ships

The honeycomb core material is a whole piece of core material made from PC (polycarbonate), PP (polypropylene), aluminum, etc., which is processed into hexagonal, circular fasting (honeycomb). The frequently used panels are PC, PMMA, PETG, aluminum or the like. Panels must be firmly bonded together with the core material using an appropriate adhesive, then it is able to demonstrate excellent characteristics of honeycomb panels, such as high specific strength, low thermal conductivity and good shock resistance, which is widely used in the yacht structure timber and yacht inner wall decoration. |

Kitchen and Bar marble countertops

Plastic honeycomb pads for Kitchen and Bar marble countertops

Thermoplastic honeycomb core material

TOPU thermoplastic honeycomb core material is a new structural material made from PP / PC / PET materials according to the honeycomb bionic principles, which is lightweight, high strength, environment protecting, waterproof and corrosion-resistant. It can be composited with different surface materials (such as wood boards, aluminum plates, stainless steel plates, marble slabs, rubber boards, etc.), and can replace traditional materials in large-scale. |  |

| Road drainage facilities of soccer fields, parks, and gardens

Core plates are made from mixing polypropylene (PP) and polyethylene (PE), with the flexibility of polypropylene and the rigid and weather resistance of polyethylene with polypropylene; membrane uses long-fiber hot rolled nonwovens, with water resistance and excellent water permeability; it is widely used in parks, gardens, pavement, soccer fields and other drainage facilities.

Note: Allianz Arena in Munich, Germany has adopted cellular drainage structure produced by our company.

|

Cowling

Honeycomb has the characteristics of lightweight, high strength, heat preservation, thermal insulation, corrosion-resistant, waterproof, and shock resistance.

Widely used in the transport shroud structure such as flight equipment. |  |

| FRP honeycomb composite board

Upper and lower surface of the honeycomb panel core can be made into fiberglass surface directly (polyester or epoxy).

Characteristics of lightweight, moderate cost, high strength, heat preservation, thermal insulation, corrosion-resistant, waterproof, and shock resistance.

Widely used in van body, car roof and trunk.

|

Lightweight wall board

Lightweight wallboard takes advantage of aviation technology, using extremely lightweight paper honeycomb core material as a core support member. Cold press it with a variety of panel material by special configured adhesive, thereby forming a composite structure of the lightweight wall. (Thickness is 91mm, and weight is 21kg/m2)

Depending on the application, the panel material can be made into gypsum plaster board, cement board, glass magnesium board, calcium silicate board and a variety of hard decorative panels. Lightweight wallboard, as the new lightweight wall material with superior performance, can be widely used in hotels, business offices, hospitals, schools, homes and other buildings in various parts of the non-load-bearing walls.

Note: The Poland Pavilion in Shanghai World Expo has extensively used plastic honeycomb lightweight wall panels. |  |

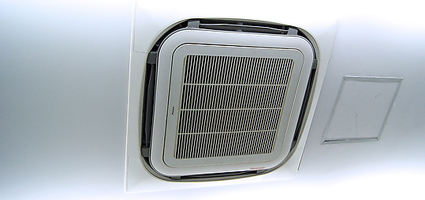

| Food display cabinets/Air curtain cabinet outlet

Display cabinets, refrigerated cabinets drift and various kinds of air volume rectifier equipment. Mount drift directly on the equipment rectifier tank. Features: air permeability rate is of 97%, the deformation under low temperature is small, with vertical not greater than 2mm and horizontal not greater than 1 mm, air volume is even, low temperature resistance is up to -40℃, and it is beautiful. |

Plastic honeycomb drift

Plastic honeycomb drift is made from raw materials of PP (polypropylene) pipe and PVC (polyvinyl chloride) sheet, with six-party-like cellular cavity structure. Mainly for equalizing the ventilation flow of frozen and refrigerated display cabinets, as well as central air-conditioning vent.

After Nano energy media processing, it can effectively kill Escherichia coli, Staphylococcus aureus, Klebsiella pneumoniae, Pseudomonas aeruginosa, viruses, etc. |  |

| Furniture Manufacturing

Honeycomb composite material’s widely application in the furniture manufacturing industry, will not only reduce the amount of wood used, but also will improve the defects of artificial wood. Use 20 mm thickness of panels as an example, if you use a 2.5mm MDF panels to make honeycomb composite panels, the materials used and the weight is only 1/4 of the solid MDF; composite panel cost only 1/2 of the solid sheet, and the composite board has the advantages of light weight, not easy to deformation, and easy to transport. Thus in Europe, more than 80% of the doors are honeycomb composite doors; most furniture plates with more than 20mm thickness are honeycomb panels. |

|